Development of a test system for automated defect analysis by means of X-ray technology for rotor blades of wind turbines

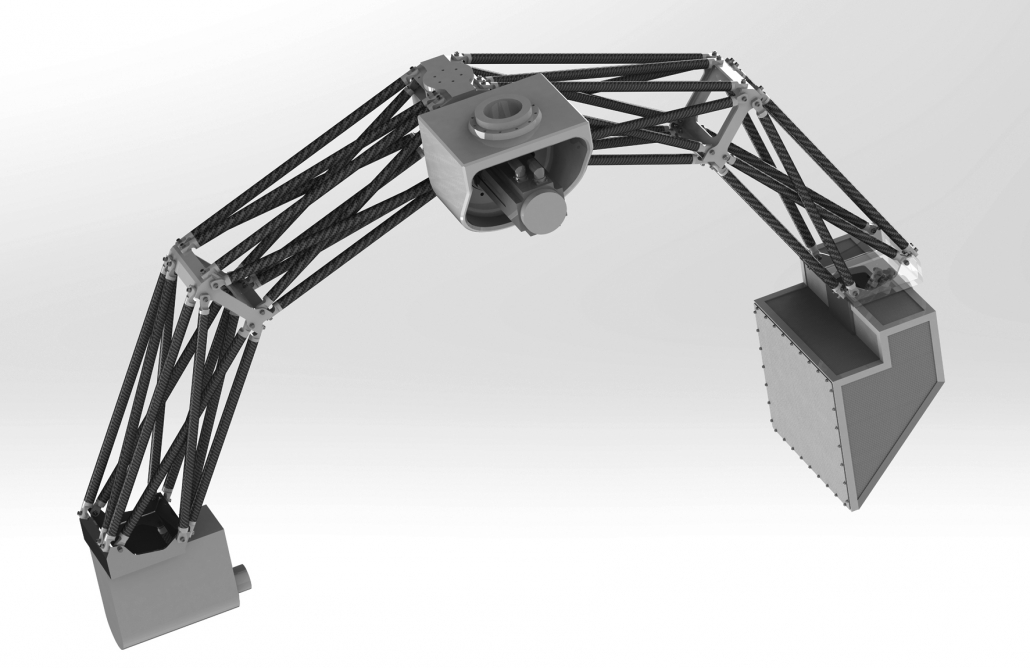

In the RoWIX joint project, a new device for the automated defect analysis of large production areas on workpieces made out of composite materials by means of X-ray technology was developed. RoWiX enables a precise recognition, visualization, and documentation of defects in the rotor blade.

The time required for the inspection of the rotor blades can be reduced with the new system, while at the same time increasing the quality and repeatability of the test.

RoWIX is a future-oriented testing concept developed as a Non-destructive testing of rotor blades, but can also be used on other large fiber-reinforced components as in the aerospace.

The essential quality features of a rotor blade, as the perfect layer build-up and the bonding of both shells, have to be checked.

A failure in any of both cases may damage or even completely destroy of a rotor blade. With RoWIX the failures can be detected at an early stage and can be repaired in time.

Project Goals

The aim of this project was the development of a system, which thanks to X-ray technology is able to produce an automated and high-precision recognition, visualization and documentation of any existing failure in the rotor blade. With RoWIX you can save both manpower and time by automating the defect analysis.

The following goals where achieved:

– Suitability for defect analysis of rotor blades of different lengths (up to 80m) and Diameters (up to 4m flange diameter).

– high detail recognizability of 200μ for a Maximum number of detected defects

– Inspection of a complete rotor blade and Evaluation of the test results within the from 4 to 8 hours (depending on the size of the rotor blade).

Resolution of the detector

per day can be checked

Length of the Blade

Flange Diameter

FRAUNHOFER IWES

FRAUNHOFER IWES