Extrusion is a process used in the areas of mold, model and prototype construction in various industries, such as e.g. in the boat and automobile industry, belongs to the standard repertoire of the manufacturing processes.

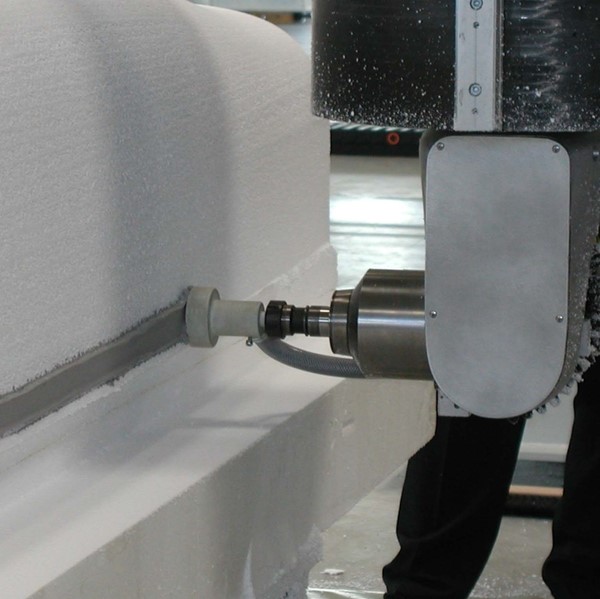

During extrusion, multicomponent synthetic resins or other pastes are applied to a carrier surface by means of a dosing or mixing system. This can be, for example, the surface of a car model made of styrofoam or a wood mold for a ship’s hull. In principle, all extruding operations can be carried out manually. However, with HSM-MODAL, customers can achieve significant benefits in many areas of extrusion, resulting in lower manufacturing costs and higher quality.

Thus, the customer is able to apply the HSM-MODAL to make the pastes evenly thick on the surfaces. As a result, no valuable material is wasted. In addition, machine application with the HSM-MODAL prevents air from being trapped between the individual paste strands. After all, these trapped air spaces cause rework to reveal holes or cracks in the model or mold surface.

Especially for large, long or hard to reach areas from the height makes it quickly positive for the customer that the HSM-MODAL achieved in contrast to manual pasting higher quality at the same or usually shorter time for extrusion. Even very long objects to be pasted, e.g. Long hulls for high-quality yachts or catamarans, the HSM-MODAL do not cause any problems, since they can be extended up to 150 m long in the longitudinal direction – even retrospectively.

Of course, mechanical processing can be carried out immediately with the HSM-MODAL after automatic pasting of the parts.