EEW PROTEC has the knowledge and know-how to afford automation solutions for a range of tasks which in the past couldn´t be carried out without the help of Men’s eyes and/or hands.

Some examples of those operations are:

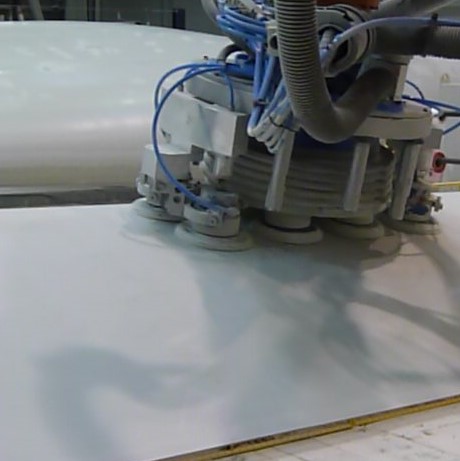

- Grinding

- Sanding

- Polishing

Those tasks have a high cost, not only because of the cost on time and money of the specialized workers but also on quality.

Previous attempts of automation have failed because of 3 main reasons:

- Parts are usually too big for an easy handling

- Parts are made out of composite

- Parts have curved forms.

In consequence, those parts have huge dimensional tolerances, they easily bend. and it is extremely hard to always fix them in the same position.

No Accuracy is Necessary in the fixture

No accuracy / measures in manufacturing and/or location is needed.

No fixture, or very simple

The system reads the surface of the part in real time. Any change or movement is detected.

Speed

Depending on the surface, the material and the configuration of the head till 3m²/min

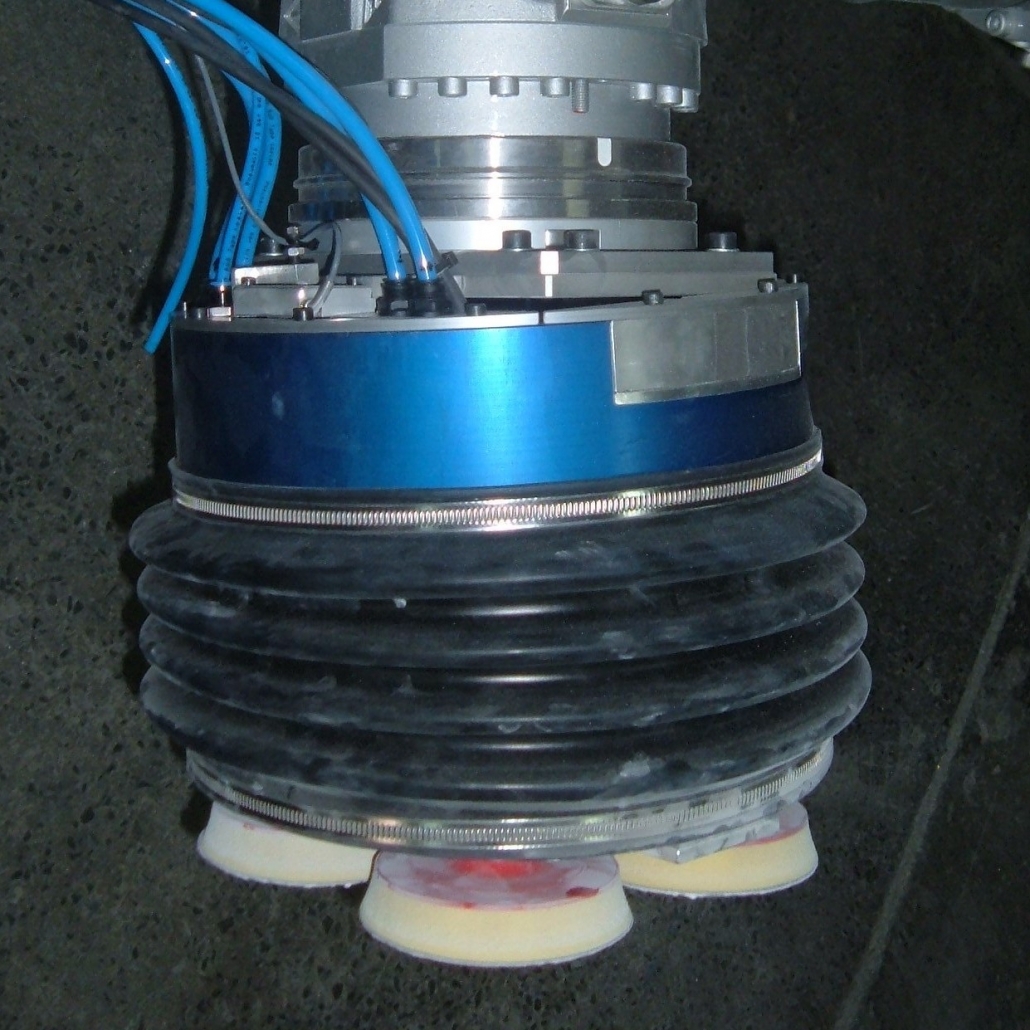

Tools

The tools used are not special, but just the usual tools in the manual process which have been slightly modified so that the automatic process is possible.

KNOW-HOW

EEW Protec has a long-time proven technology in the field of grinding. Applications are already in use in markets such as aerospace, wind industry and others.

The technology has many interesting features:

- Checks the current position of the tool.

- Compares on the fly with the program running.

- Compares with old stored trajectories of similar parts (self learning)

- Compare with CAD data if available

- New trajectories are automatically calculated