CONCEPTION

Design of complex parts fulfilling requirements.

We are specialist in the conception and design of Carbon fiber parts.

CAEmate experts of Numerical Simulations using Finite Element Methods. Our team of engineers can provide support during all phases of the design cycle, right from the inception.

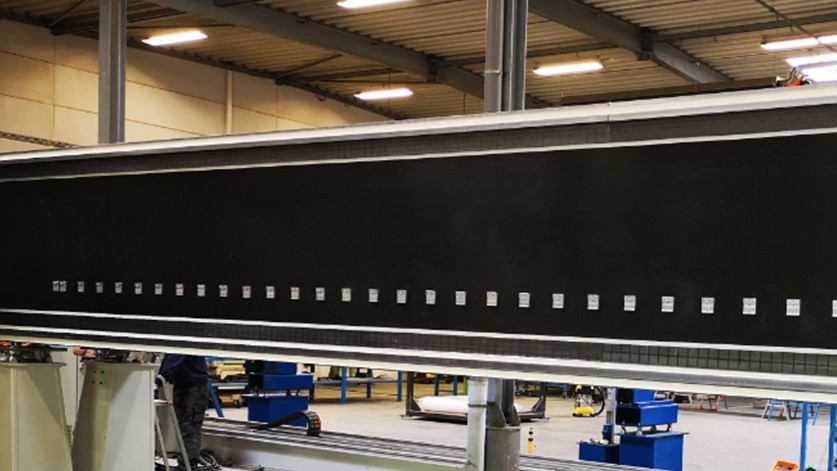

We are not only specialized in the conception of Carbon Fiber parts but also on the manufacturing processes as infusion, Layup, assembly, bonding, surface treatments (Sanding, polishing …) or even the repair of damaged materials …

We also offer automatic non-destructive analysis processes,

We have the experience and necessary know-how.

We infuse resin, we layup single fibers, we cut and handle prepregs…

Design of complex parts fulfilling requirements.

FEM. Design and structural calculations.

In-House Manufaturing of any part

If you manufacture, we can help you to automate your process.

Ultrasonic cutting machines vibrate a cutting tool (usually titanium blades) at a high frequency. They are used to cut carbon fiber, glass fiber, laminates, films, cork, prepreg, rubber, leather, plastic, food, and honeycomb materials. Ultrasonic cutting machines are also used to produce honeycomb parts and cut materials such as Kevlar.

EEW-PROTEC specializes in the precision machining of advanced materials and complex shapes.

Sanding of complex carbon fiber shapes.

Our Surface tracking technology allows the sanding head to follow with great precision the surface to be treated regardless of its position, size, shape, or rigidity of its support.

The increasing necessity of greater flexibility in the development of plastic and fiber parts, and the exigencies of greater finishing quality have demanded the application of automated methods which also avoid the heating of the product and the formation of dust during the cutting process.

The Waterjet cutting fulfills these requirements.

EEW-PROTEC and its HSM-MODAL is the perfect partner to cut big parts made out of composite.