The HSM-MODAL can be easily coupled with a Laser Cutting system. The speed and accuracy of our CNC system make the combination unique.

Of course, various processes can also be integrated with the HSM-MODAL and thus a unique performance can be achieved, e.g. laser cutting in combination with milling.

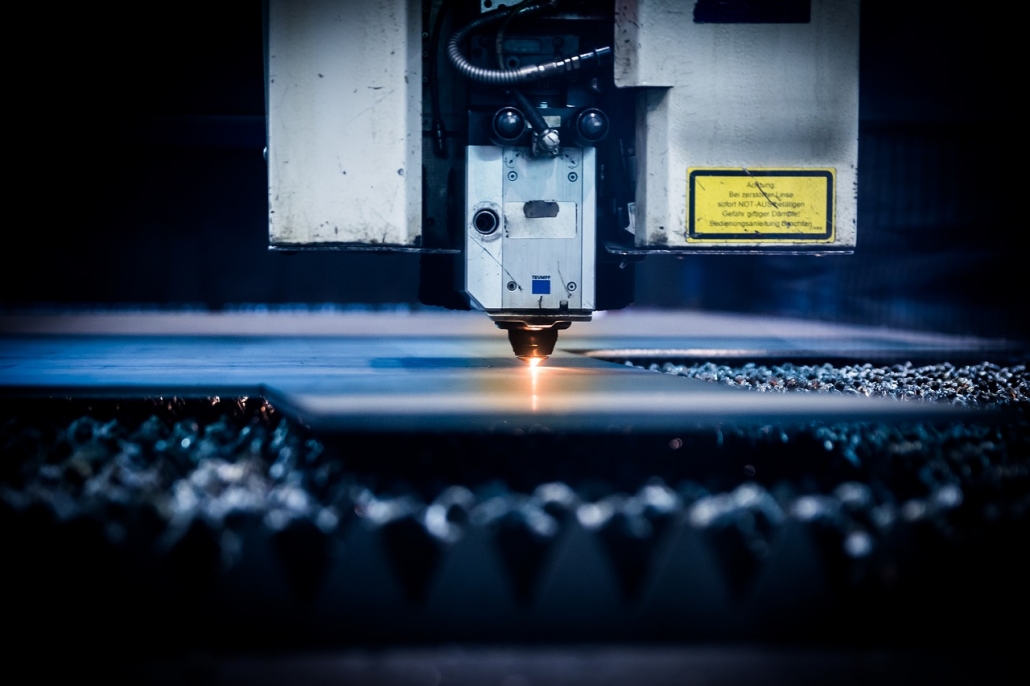

Laser cutting offers the customer several technical advantages. Lasers enable very accurate cutting, i.e. depending on the laser, cutting gaps of approx. 0.2 mm or even less can be achieved. At the same time, very good right angularity of the cutting edges is guaranteed. Thanks to state-of-the-art impulse techniques, some lasers can also accurately cut out very complex shapes with pointed edges and small drill holes.

With HSM-MODAL, and an appropriate laser, the customer can also cut large objects without any contact. Thus, objects can be cut without damaging their material surfaces. The customer can easily construct a laser-cutting path lengthways due to the open architecture of HSM-MODAL if required.

If customers have the choice between laser and water cutting, they should compare the two methods in order to make the right decision in advance. In any case the customer has the flexibility to equip HSM-MODAL with both systems.

Comparison

| Waterjet Cutting | -Cutting of almost all materials and large material thicknesses possible.. -No material distortion due to heat. -Narrow kerfs of 0.3mm possible. -Very good cut quality. -Good automation of the process. |

|---|---|

| Laser Cutting | -High contour accuracy when Cutting small or medium thick sheets. -Fast Cutting of thin sheets possible. -Cutting of sophisticated shapes possible, i.a. small holes and acute angle. -Right-angled cutting edges Low efficiency (CO2 laser up to 10%). -Very good automation. -Very small kerf width (0.2 – 0.4 mm). |

| Plasma Cutting | -Cutting of all (electrically) conductive materials possible. -Alternative when Cutting High-alloy steels and aluminum materials in medium and larger thicknesses. -Very suitable for cutting structural steel from thicknesses up to 30 mm -Cutting High-strength structural steels with Low heat input possible. -Fast Cutting even of hard materials possible. -Very good automation. |